HOME > Manufacturing and Sales > Drilling Tools

If you concern the quality, you will reach TONE.

Product introduction

| Type | Nominal size | |

|---|---|---|

| Drill rod | With coupling | T40.5、T50、T60B |

| Friction welded type | MT50、MT60、T73、T90、T120、T140 | |

| For SONIC Drill | SONIC 4-1/2"、SONIC N 6-5/8"、SONIC 8-5/8" | |

| wireline rod | AQT、BQT、NQT、HQT、PQT、NTG、HTG | |

| SONIC wireline tools | For SONIC Drill | TS-118 |

| Shield Pipe | For horizontal drilling | TR80、TR105、TR130、TR165、TR216 |

| Casing pipe | For bored wall potection | 43、53、63、73、83、97、112、127、101.6(For EP drill series) |

| Hoisting Water Swivel | Water circulation tools | CH、DH、EH、FH-6、FH-12 |

| Hoisting Swivel | Lifting/lowering tools | B-4、B-6、B-7 |

| Rod Holder | Holding tools | RH-45、RH-85 |

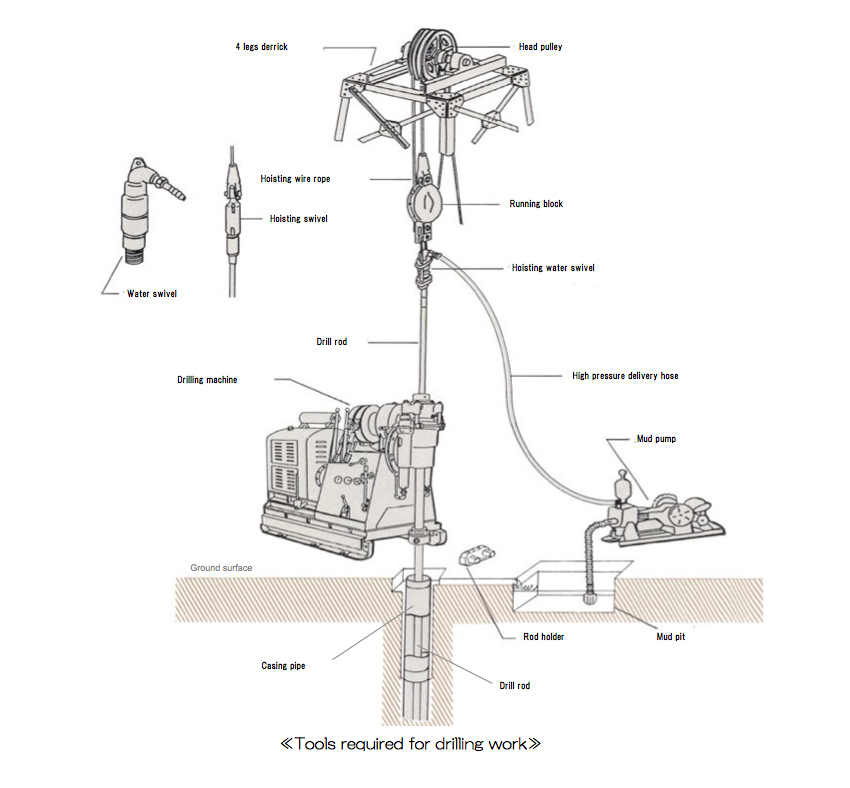

Drill Rod

Drill rod or drill pipe is an important tool to transmit the rotation and feed force generated by drilling machine to drill bit. Drill rod has another function to deliver circulation fluid from drilling pump to drill bit through inside drill rod for cooling the bit and for discharging the cuttings to ground surface.

Drill Rod (with coupling)

| Nominal size | Outer diameter (mm) D1 |

Inner diameter (mm) D2 |

Wall thickness (mm) t |

Coupling ID (mm) D3 |

Sandard length (m) L |

Weight (kg/m) |

Remarks |

|---|---|---|---|---|---|---|---|

| T40.5 | 40.5 | 31 | 4.75 | 17 | 1 | 4.6 | JIS Standard |

| T50 | 50 | 37 | 6.5 | 22 | 1 | 6.5 | 〃 |

| T60B | 60 | 47 | 6.5 | 25 | 1 | 11 | 〃 |

Drill Rod (friction welded type)

Rotary friction welding method joins two steel objects by utilizing frictional energy generated by high speed rotational contact of two steel objects, by adding high pressure force.

| Nominal size | Outer diameter (mm) D1 |

Inner diameter (mm) D2 |

Wall thickness (mm) t |

Coupling ID (mm) D3 |

Sandard length (m) L |

Weight (kg/m) |

Remarks | |

|---|---|---|---|---|---|---|---|---|

| On male threads | On female threads | |||||||

| MT50 | 50 | 37 | 6.5 | 22 | 22 | 1 | 8.2 | EP: ECOPROBE |

| MT60 | 60 | 47 | 6.5 | 26 | 26 | 1 | 10.2 | 〃 |

| T73 | 73.1 | 59.1 | 7 | 35 | 44 | 3 | 11.8 | For water well drilling |

| T90 | 88.9 | 74.9 | 7 | 44 | 50 | 3 | 15.5 | 〃 |

| T120 (3-1/2IF) | 120.7 | 102.7 | 9 | 68 | 68 | 3 | 28 | 〃 |

| T140 (4 IF) | 139.8 | 119.8 | 10 | 80 | 80 | 3 | 38 | 〃 |

Drill Rod (for Sonic Drill)

| Nominal size | Outer diameter (mm) D1 |

Inner diameter (mm) D2 |

Wall thickness (mm) t |

Coupling ID (mm) D3 |

Sandard length (m) L |

Weight (kg/m) |

Remarks | |

|---|---|---|---|---|---|---|---|---|

| On male threads | On female threads | |||||||

| SONIC 4-1/2" | 114.3 | 99.7 | 7.3 | 76.2 | 76.2 | 3 | 22 | For SD |

| SONIC N 6-5/8" | 168.3 | 153.7 | 7.3 | 127.6 | 139 | 3 | 34.8 | 〃 |

| SONIC 8-5/8" | 219.1 | 205.1 | 7 | 181 | 181 | 3 | 44.5 | 〃 |

Wireline Drill Rod

Friction welded type for BQT, NQT, HQT, NTG and HTG size will be optionally available.

| Nominal size | Outer diameter (mm) D1 |

Inner diameter (mm) D2 |

Wall thickness (mm) t |

Coupling ID (mm) D3 |

Sandard length (m) L |

Weight (kg/m) |

Remarks |

|---|---|---|---|---|---|---|---|

| AQT | 44.5 | 35 | 4.75 | - | 3 | 4.6 | Core recovery |

| BQT | 55.6 | 46 | 4.8 | - | 3 | 6 | 〃 |

| NQT | 70 | 60.3 | 4.85 | - | 3 | 7.8 | 〃 |

| HQT | 88.9 | 77.8 | 5.55 | - | 3 | 11.4 | 〃 |

| PQT | 114.3 | 103.2 | 5.55 | - | 3 | 15.5 | 〃 |

| NTG | 70 | 60.3 | 4.85 | 54 | 3 | 8.5 | 〃 |

| HTG | 88.9 | 77.8 | 5.55 | 70 | 3 | 12 | 〃 |

SONIC Wireline tools

Sonic Wireline sampling tool is developed specifically for SONIC Drill with powerful vibration force.

SONIC Wireline tools eliminates the need for raising and lowering the drill rod after each sample collection, which results in a significant improvement in operational efficiency.

SONIC Wireline tools

| Nominal size | SONIC Wireline rod | SONIC Wireline bit | |||

|---|---|---|---|---|---|

| Outer diameter (mm) |

Inner diameter (mm) |

Weight (kg/m) |

Set outer diameter (mm) |

Set Inner diameter (mm) |

|

| TS118 | 118 | 100 | 24.7 | 126 | 68 |

Shield Pipe

Shield pipe is utilized for horizontal drilling for dewatering, water drainage or coring purpose. Horizontal drilling contains very severe drilling conditions such as the decline of cutting disposal efficiency, frequent occurrence of water gush and collapse compared with vertical hole drilling, in addition, siheld pipe to be used for horizontal drilling requires high durability to bear high rotating torque.

Shield Pipe

| Nominal size | Outer diameter (mm) D1 |

Inner diameter (mm) D2 |

Wall thickness (mm) t |

Sandard length (m) L |

Weight (kg/m) |

Remarks |

|---|---|---|---|---|---|---|

| TR80 | 80 | 68 | 6 | 1 | 10.8 | Horizontal drilling |

| TR105 | 105 | 90 | 7.5 | 1 | 18 | 〃 |

| TR130 | 130 | 115 | 7.5 | 1 | 22.8 | 〃 |

| TR165 | 165.2 | 145.2 | 10 | 1 | 38 | 〃 |

| TR216 | 216.3 | 195.7 | 10.3 | 1 | 52.3 | 〃 |

Casing Pipe

Casing pipe is the tubing to be installed in the drilled hole to protect bored hole from caving while drilling. In addtion to bored hole protection, casing pipe has the functions for the prevention of lost circulaton, the reduction of friction between drill rod and bored hole, and for making the recovery of drill strings left in the hole by the accident easier.

Casing Pipe

| Nominal size | Outer diameter (mm) D1 |

Inner diameter (mm) D2 |

Wall thickness (mm) t |

Sandard length (m) L |

Weight (kg/m) |

Remarks |

|---|---|---|---|---|---|---|

| 43 | 43 | 37 | 3 | 3 | 3.0 | JIS Standard |

| 53 | 53 | 47 | 3 | 3 | 3.7 | 〃 |

| 63 | 63 | 57 | 3 | 3 | 4.4 | 〃 |

| 73 | 73 | 67 | 3 | 3 | 5.2 | 〃 |

| 83 | 83 | 77 | 3 | 3 | 6.0 | 〃 |

| 97 | 97 | 90 | 3.5 | 3 | 8.1 | 〃 |

| 112 | 112 | 105 | 3.5 | 3 | 9.4 | 〃 |

| 127 | 127 | 118 | 4.5 | 3 | 13.6 | 〃 |

| 142 | 142 | 133 | 4.5 | 3 | 15.8 | 〃 |

| 101.6 | 101.6 | 91.6 | 5 | 1 | 11.9 | For EP drill series |

Hoisting Water Swivel

Water swivel has a function for circulating drilling fluid from mud pump through rotating drill rod while drilling. The one side is connected with swivel hose and the other side is connceted with drill rod. When drill rod connected with water swivel is lowered or lifted, water swivel is connected with hoisting wire rope by the pin, and water swivel is hence called as hoisting water swivel.

Hoisting Water Swivel

| Model | Load capacity (t) |

Max. pressure (MPa) |

Max. rotation speed (rpm) |

Max. flow volume (L/min) |

|---|---|---|---|---|

| CH | 1 | 2.5 | 900 | 80 |

| DH | 2 | 2.5 | 900 | 130 |

| EH | 4 | 2.5 | 900 | 130 |

| FH-6 | 6 | 6.9 | 500 | 500 |

| FH-12 | 12 | 6.9 | 300 | 850 |

Hoisting Swivel

Hoisting swivel which end is connected with the socket of hoisting wire rope is used for lifting and lowering drill rod or casing pipe. There are two types of hoisting swivels. The one is telescopic spindle type (Model B-6, B-7 and B-8) to protect the threads of drill strings when disconnecting, and the other is fixed spindle type (Model B-4) with swivel system only.

Hoisting Swivel

| Model | Load capacity (t) |

Type of wire socket (No.) |

Size of wire rope (mm) |

|---|---|---|---|

| B-4 | 2 | 4 | 9~12.5 |

| B-6 | 10 | 6 | 14~18 |

| B-7 | 20 | 7 | 18~20 |

| B-8 | 30 | 8 | 22.4~25 |

Rod Holder

Rod holder is used for holding drill rod at ground surface when lifting from the hole or lowering into the hole. There are two types of rod holder. The one is manual type with two jaws and frame (Model RH-45, RH-85) and the other is hydraulically clamping type (Model CH-60A).

Rod Holder

| Model | Load capacity (t) |

Max. rod size (mm) |

Operating method | Remarks |

|---|---|---|---|---|

| RH-45 | 6 | 44.5 | Manual | |

| RH-85 | 6 | 90 | Manual | |

| CH-60A | 6 | 90 | Hydraulic | Set pressure: 3.9 MPa |