HOME > Engineering Works > Ground Improvement Work

We have experiences utilizing various methods for Ground Improvement Works.

Followings are the introduction for Ground Stabilizing Method.

Epo-Column Method

Deep soil improvement actualizing high quality and cost reduction .by means of multi-mixing blades and cutting blades rotating to different direction each other.

This technology is positioned as one of deep soil improvement method applied for loose ground which depth of improvement exceeds 10 m and is sometimes applied to medium-depth soil improvement method with improved depth of 4 - 10 m.

Features

Contribution to cost reduction

Construction of large diameter soil-cement column with upto max. 2500mm is possible and enbales the cost reduction and shortening working period.

Forming of a homogeneous and high quality column

Outer and center blade of mixing blades are rotated to same direction and middle and cutting blade are rotated to opposite direction. This action creats a synergisitic effect of cutting action and kneading action to form a homogeneous soil-cement column.

Furthermore, since outer blade holds mixed soil in order not to squeeze outward, a specified homogeneity of cylindrical forming is possible.

High mixing productivity

By means of mixing with low speed and high torque rotation, and locking the shafts with outer and middle blades at both sides, mixing in gravel and boulder layer is possible.

Wide range of column size

The range of column size is selected for 600 - 2500 mm.

CDM Method

Deep mixing method by means of two shaft mixing blades which has a lot of working experiences on shore and off shore.

Features

Availability of offshore and onshore operation

For offoshore operation, operation system using a special vessel is provided.

High reliability of construction management

Construction management system for slurry flow rate, working depth and rotation of mixing blades, and control mangement system for slurry plant are provided.

Reliability for obtaining a certain strength

Since blending quantity of solidification material for cement slurry can be adjusted based on target soil condition, a specified strength can be certainly obtained.

Ensured workability

The system is composed of twin mixing blades with the diameter of 1000 - 1200 mm to ensure high mixing productivity.

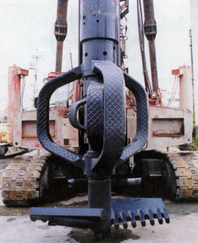

RM Method

Surface and medium depth soil improvement method possessing a large number of working records for very sof ground by means of rotary mixing blades .

Features

Smooth operation on ultra soft ground

Operation on ultra soft ground is carried out by operation system by means of a specially designed amphibian mud vehicle.

Operation with high mobility on soft ground

For the place with soft ground where the trafficability is required, a specially designed excavator based machine with high mobility is actively utilized.

Efficient solidified forming

Standard solidified forming pattern is latticed pattern to enable efficient operation.

Reliability for obtaining a certain strength

Since blending quantity of solidification material for cement slurry can be adjusted based on target soil condition, a specified strength can be certainly obtained.

Chemical Grouting Method

Active use as liquefaction countermeasure and to enhance the safety of underground work by injecting water glass based chemical agent.

Features

High permeability into the ground

Water glass based solution has high permeability into the ground since this does not contain any grains, not like cement slurry.

Compact equipment facility suitable for the operation at restricted space

Since the space required for equipment facility that has a simple structure is small, the operation at restricted space or under limited headroom is possible.

Applicable to various sites and soil conditions

Due to less noise and vibration, the impact of environmental effect is quite small and this method is accplicable to most ground conditions because of a variety of methods and materials.

Less volume of industrial waste

Compared with other methods, the created volume of industrial waste becomes less so that this method can be friendly to the environment.